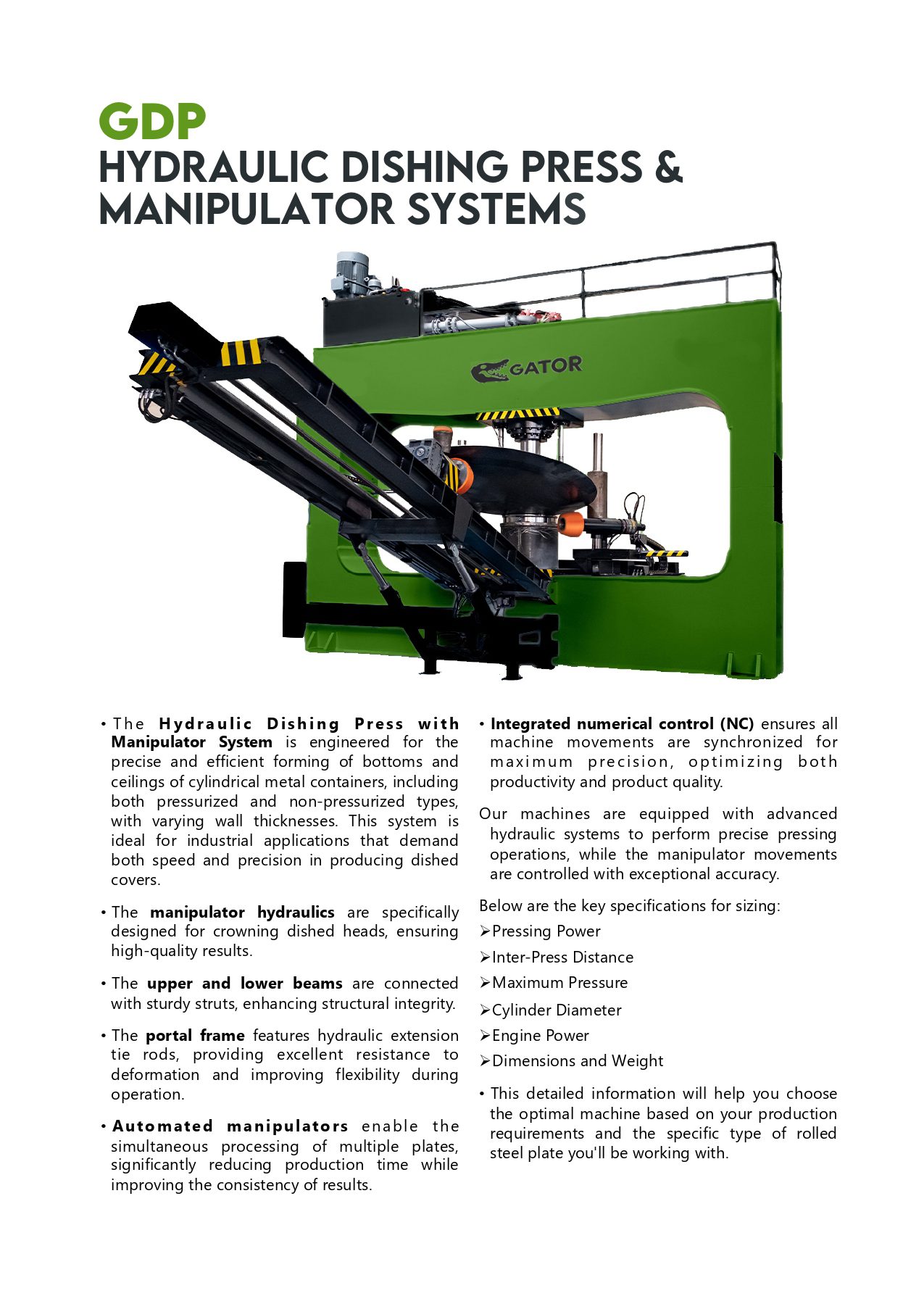

GDP HYDRAULIC DISHING PRESS & MANIPULATOR SYSTEMS

Description

• The H yd r a u l i c D i s h i n g P r e s s w i t h Manipulator System is engineered for the precise and efficient forming of bottoms and ceilings of cylindrical metal containers, including both pressurized and non-pressurized types, with varying wall thicknesses. This system is ideal for industrial applications that demand both speed and precision in producing dished covers.• The manipulator hydraulics are specifically designed for crowning dished heads, ensuring high-quality results.• The upper and lower beams are connected with sturdy struts, enhancing structural integrity.• The portal frame features hydraulic extension tie rods, providing excellent resistance to deformation and improving flexibility during operation.• Automated manipulators enable the simultaneous processing of multiple plates, significantly reducing production time while improving the consistency of results.• Integrated numerical control (NC) ensures all machine movements are synchronized for maximum precision, optimizing both productivity and product quality. Our machines are equipped with advanced hydraulic systems to perform precise pressing operations, while the manipulator movements are controlled with exceptional accuracy. Below are the key specifications for sizing: ØPressing PowerØInter-Press DistanceØMaximum PressureØCylinder DiameterØEngine PowerØDimensions and Weight• This detailed information will help you choose the optimal machine based on your production requirements and the specific type of rolled steel plate you’ll be working with.